Week 1

Foreword

Since it’s a pain to look at a friends phone to see what they’re working on, these posts will serve as my way to semi-formally document the restoration process and keep friends and family up to date.

In advance, I apologize for any grammatical or spelling errors. I will make sure the editor takes a good look at each post…

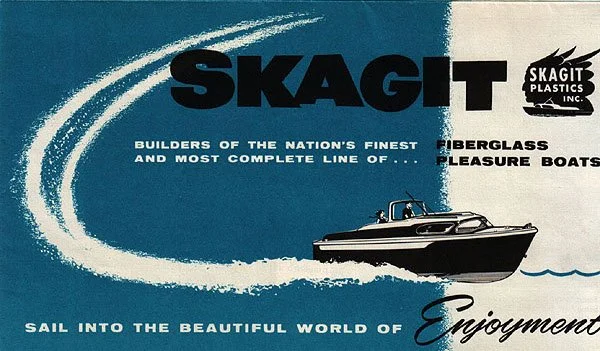

Fiberglass | The 1959 Skagit Sportster

Fiberglass was introduced in the 1930s, but didn’t see much use during war time construction of larger ships. Polyester resin did make an appearance during the 40’s in aerospace applications for fuel cell liners. Companies like Bell Boy, of Bellingham Washington, realized the commercial opportunity for fiberglass in recreational watercraft. By the mid 50’s, Bell Boy had designed a wide selection of models between 8 and 21 feet long to satisfy just about any water-goer.

Thanks to the enlarged ship building capacity and workforce brought about by WWII, several other shipyards in the Puget Sound area pivoted from making war ships to make smaller crafts for the post-war market to enjoy.

As you would expect, the design language of small fiberglass boats in this era was similar to the post-war automobile; however, where cars were produced in massive numbers to fulfill the needs of millions of households, these boats were built in significantly lower volumes. This lower production count meant some manufacturers could offer much more radical and sometimes even completely bespoke designs without taking on the burden of expensive tooling for mass production. Having said that, the tooling was probably still expensive…just not as expensive as launching a new Ford sedan..

By comparison, these little vivacious pieces of plastic required far less maintenance than a traditional wooden boat and could be ordered right out of a magazine in your desired specification. The manufacturing process lended itself well to making complex curves and geometries that would be either cost prohibitive or impossible to produce out of wood. Tail fins, lower windshield, waterskiing bridle - you name it. With these relatively inexpensive pleasure crafts being considered more like a toy or leisure vehicle, families were able to go cruise around in a little space-age vehicle like George Jetson. A prime example is the Bell Boy Bikini 20’ - a purpose built 100mph family racer designed by Ted Jones.

By 1954, Bell Boy had produced over 5,000 boats in their various plants. Around that time, an outfit in LaConner Washington decided they wanted to enter the market with a boat of their own. Impressed by the local competition, the owners of Dunlap Towing Co. poached the very best right from Bell Boy - Howard Roberts. Within a year, Roberts had production up and running and Skagit boats started hitting the water.

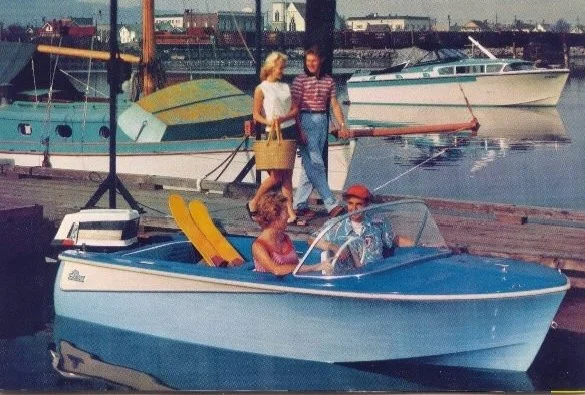

My particular boat was constructed in 1959 and delivered with an Evinrude Lark 35 Golden Jubilee - as seen in the photograph later in the article. The production of all Skagit boats in 1959 totaled just 300 units spread across the 14 models. In sum, Skagit Plastics Inc produced no-more than 1000 boats - ranging from 8 feet in length up to 31 feet long.

Coming in at just14 feet long, my piece of Puget Sound history floats-in a hair shorter than a Miura, just a few inches longer than a 356, and a bit narrower than a BMW E30. I know, that’s a useless way to measure a boat…

It weighs, allegedly, 375 lbs from new. A lightweight unit considering when that number includes all of the trimmings; however, if this is anything like a Lotus Elan, I’m sure some were laid up heavy-handed and others lacking resin.

At the time, the new ‘59 Sportster campaigned several new performance features - such as the “Air-O-Glide Bottom” and a revised structural design which included a “Stiffener Web” bonded directly to the inner side of the hull. I will get into this construction as this project goes along, but all you need to know is - thank heavens it isn’t wood-cored.

Compared to its contemporaries, the design of the Sportster is much more mature in the styling department. It’s elegant details that don’t shout at you like big tail fins or bright colors - although you could order those colors too. It can be dressed up to a suit or down to a small pair of trunks .. or less! Mine is simply black-over-white, seats four, and is usually ready to go at a moments notice.

It skips along over glassy water and bobs like a cork in chop.

It’s a floating sunset cocktail party.

It’s a family sedan.

It’s just fun.

It’s informally referred to as Cork or Orca II. The former for its ride characteristics in rough water and the latter with respect to Grandpa Jacks first boat - Orca.

Workspace

Before I can even begin to describe the task ahead, I need to clear a space to work. Like in any old garage, tools and materials get squirreled away year after year. This trickling accumulation, compounded by the lack of a “spring cleaning”, a dust off, or any refresh leaves you with the messy situation I face today.

Basically, there’s a lot of shit in this garage.

Walking into a garage to find five matching tool chests is rare. It’s even more rare that they’re organized. I’m lucky with the former, but not the latter. Unfortunately, they don’t suffice to store all of the different odds and ends in this garage. Sure, the garage is large enough to have a sizable workbench, pressure-washer, lawnmower, and (once upon a time) two Nimitz Class1997 Lincoln TownCars - in Cartier spec- situated two abreast; however, the garage needs a once over.

In short, I pulled everything to the middle of the room and started to form piles of tools and trash. Several hours later. The boat was repositioned to the north side of the garage and the two - or so - dozen cans of old paint, propane, and butane were ready to go off to the appropriate disposal depot.

All said and done we found ourselves with more room to park and just enough thinking space to start work on the boat.

The goal..

Now that the patient has been moved to the right side of the operating room, we should discuss the procedure. The backbone of this 64 year old craft is ailing. After years of use and unknown abuses, it’s time for an update. There’s no doubt that this boat wasn’t envisioned to last even a quarter of its life so far. Upon first glance under the skin…I’m surprised it’s still afloat. Sure, there are probably a handful of these still kicking around and the red-herring that’s still in pristine condition, but I guarantee that they don’t see use like this one.

At this point, it’s feels sort of like my duty to keep it alive. The tired hull and cracked benches are probably a season or so away from being a real issue. It has seen its first few years on the lake as a patina-queen, but now it’s time to tidy things up so it can go another 64 years.

When I’m done, good luck finding another one like it.

On order

New floor, paint, and un-fuck all the debauchery that’s going on under the gunwale. By the time this is over I may add amateur boat builder to my CV.

The boat will also live on in the virtual world…

More on that later.

Inventory

As much as I want to dive into tearing this thing apart, I need to assess the order in which components will be removed to keep myself on track. I’ve taken several components of the boat so far. The rub rail and extrusion caps - see pictures - being the first to come off. The smaller trim pieces will be cataloged, photographed, and scanned for re-engineering and or just for posterities sake.

The tentative order of events will be: outboard motor removal, fiberglass top removal, floor removal, floor structure and hull repair, floor installation, seats and top repair and assembly, and then nurture the paint and gelcoat …motor install and service…apply sun block…don’t forget the drain plugs.

No Secrets…

The first week has seen more contemplation than action. I’ve spent most of my time upside down and contorted to look around and take notes. Carefully disassembling the more delicate trim. All this climbing around has helped me visualize how I will approach each area of concern - and there are a few.

I have a good feeling about which parts are original. I’d prefer to remain as original as possible, but I won’t shy away from some structural redesign. At this point there aren’t many original boats to use as reference, so I will use my best judgement.

I knew it wasn’t going to be a quick project, but I’m going to see it through.

There is no alternative.

During the few years of my stewardship I’ve invested in several areas of the boat, but mostly the last two feet of it. A new transom was installed by a local shop in the Tacoma area. Not too far from where the brand new motor was equipped. The 3 cylinder Mercury 40-HP outboard with electronic fuel injection, power tilt and trim, and a warranty provides just the right amount of poke to get this aqua sedan on plane with a full load…provided the balance is on point. On calm waters, the boat feels like an absolute rocket ship at full throttle….40 horsepower is plenty here. I still have the original Evinrude Lark Golden Jubilee 35..another project to be had.

Anyway, back to the work I’ve had done so far. Let’s just say that the quality of work I thought I received was on par with what I paid for - reluctantly, I feel like a bit of a jackass.

For whatever reason, I never went to inspect areas of the boat that I’m looking at now. Back then, I was just happy that it didn’t creak and it looked ace. Don’t get me wrong, the guys at that shop did a great job on the transom and enabled me to go create some of the most incredible memories I’ve had in Seattle, but they did cut a few corners…. or fiberglass over the corners….. It appears that up under the gunwales they decided to fiberglass over the metal extrusion that holds the top half of the boat to the hull. This just means more work for me to put right because I can’t just ignore it.

….not cool

This rub rail end cap was bonded to the transom… see next photo for other side, which barely touches the top.

This side didn’t fit well, but I can correct that when I go to reinstall the top.

Bummer to find, and I’m sure there will be more of this elsewhere on the boat. A good lesson to be a bit of a hawk when it comes to evaluating someone else’s work.

I decided to cut a hole and pulled up a sample of the floor to measure the laminate thickness. I’m inching closer to ordering my materials and the thickness of this floor will dictate the option of Coosa Bluewater 26 board I will order. I’ll cover the Coosa composite board in a later post, but all-in-all it’s going to be a worthy investment. The wood was approximately 1/4” thick with what appeared to be a very tired single layer of fiberglass…or webbing…unclear.

Luckily for me here, the floor wasn’t glued to the stringers beneath. Moving forward, this will result in less time to removal of the rest of the floor. Peering through the hole shined light on a thing I didn’t want to see - water… about a half inch of it. Given that I was toward the front of the hull that meant I have about 10 feet of water behind me...

Focus is off… but trust me on the water…it’s in there.

Next week…

Motor needs to come off..

A few very generous friends at work were willing to lend an engine hoist and the beginnings of a stand for the motor. I plan to remove the motor at the power tilt tube pivot point as to keep the mounting plate attached to the transom to remove the risk of damage there. Further examination this week will tell me if that is the best path forward.

The plan is to sand/grind off the mess at the back to gain access to the bolts holding the aft-most section of fiberglass on. Next week, I will include a diagram of the boat so this should all make more sense then.

See you next week

Thank you…

Special thanks go out to Rick Danielson and Lorraine for letting me be the custodian of this stellar boat. It has provided me some of my favorite moments in Seattle. The Sportster has brought a smile to countless folks around the Lake Washington and Lake Union area. I’ll keep Mark’s enthusiasm going - perhaps with less duck tape. Can’t wait to get you out on the water!

Great Grandpa Reinke in his Bell Boy off Vashon Island circa 1960. May need to recreate this..

..and of course, thank you to my Grandma for letting me take over her garage and supplying a proper helping of cinnamon rolls along the way. I have a lot of cribbage and backgammon games to win in the coming months…

——

If you made it this far, thank you for humoring me.

-JHR