University of Washington Formula Motorsport - Pedal Assembly

Design Brief: Design the lightest, stiffest, and manufacturable pedal assembly for the Team 31 car. The pedals are milled from 7075 Aluminum and accompanied by several available high performance springs, sensors, brake master cylinders et cetera.

The system was designed in compliance to the 2019/20 FSAE rulebook and manufactured on-site at the University of Washington.

Due to the pandemic, they were never used in competition… One day.

Considerations

-

Accelerator:

Must return to original position after actuation.

Two return actuators must be used in case of failure.

The brake pedal must be:

Fabricated from steel, aluminum, or titanium.

Designed to withstand a force of 2000N without any failure of the braking system or pedal box.

Monitored by a brake over-travel switch.

Critical Fastener Requirements:

Any Critical Fastener must meet, at minimum, one of the following:

SAE Grade 5

Metric Grade 8.8

AN/MS Specifications

Equivalent to or better than above, as approved by a Rules Question or at Technical Inspection.

-

Factors:

Braking system engineer:

Desired mechanical advantage ~1.5.

Optimized master cylinder bores.

Ergonomics:

Accommodation for drivers ranging from 5th percentile female to the 95th percentile male.

Adjustable pedals are not a requirement; however, points can be earned for this accomodation.

-

We want:

The lightest and stiffest pedal assembly possible.

Design in-house components using FEA topology optimization.

Harness in-house manufacturing capabilities.

Traditional CNC machining.

3D printed Titanium*.

Ease of assembly.

Improve on serviceability from previous designs.

Accessibility to adjustments once installed.

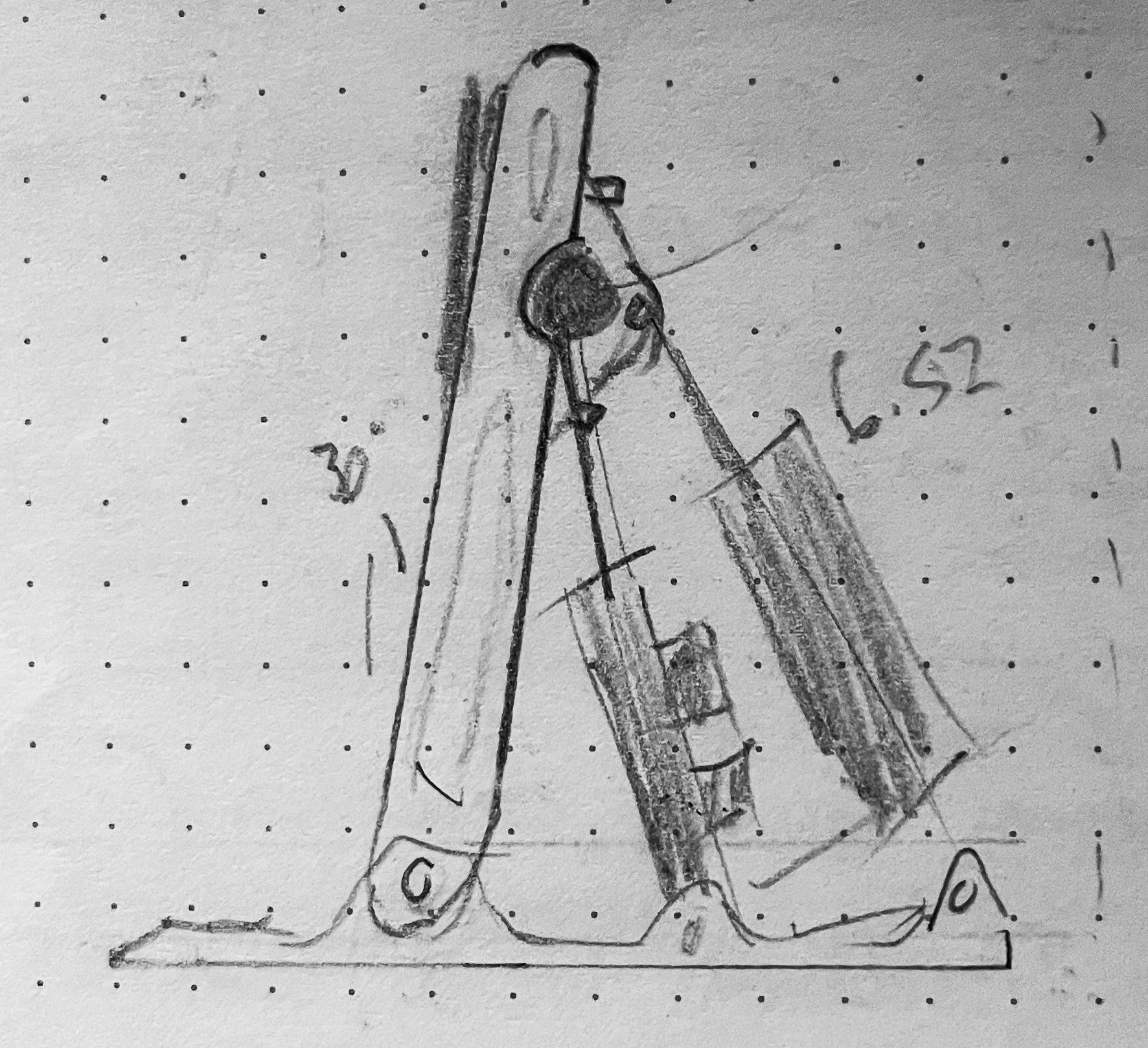

Rough sketching

..trying to understand the overall architecture and connections.

Configuring approximate loads..

..I want to make sure we understand the loads at each interface as we design the supporting mechanical structure.

Material Selection

-

6061 Aluminum

Yield Strength = ~ 276 MPa.

Tensile Strength = ~ 310 MPa.

Higher silicon content.

6061 aluminum is one of the most popular aluminum grades available because of its good strength, formability, weldability, machinability, and corrosion resistance.

-

7075 Aluminum

Yield Strength = ~ 503 MPa.

Tensile Strength = ~ 572 MPa.

Great strength to weight ratio.

Harder material to machine when compared to 6061.

The shear strength of 7075-T6 is estimated to be 1.5 times that of 6061-T6.

-

3D Printed Titanium

Ti6Al4V

Yield Strength = ~ > 900 MPa*.

Tensile Strength = ~ > 980 MPa*.

Enables complex geometries not attainable with traditional machining processes.

Minimal post processing.

-

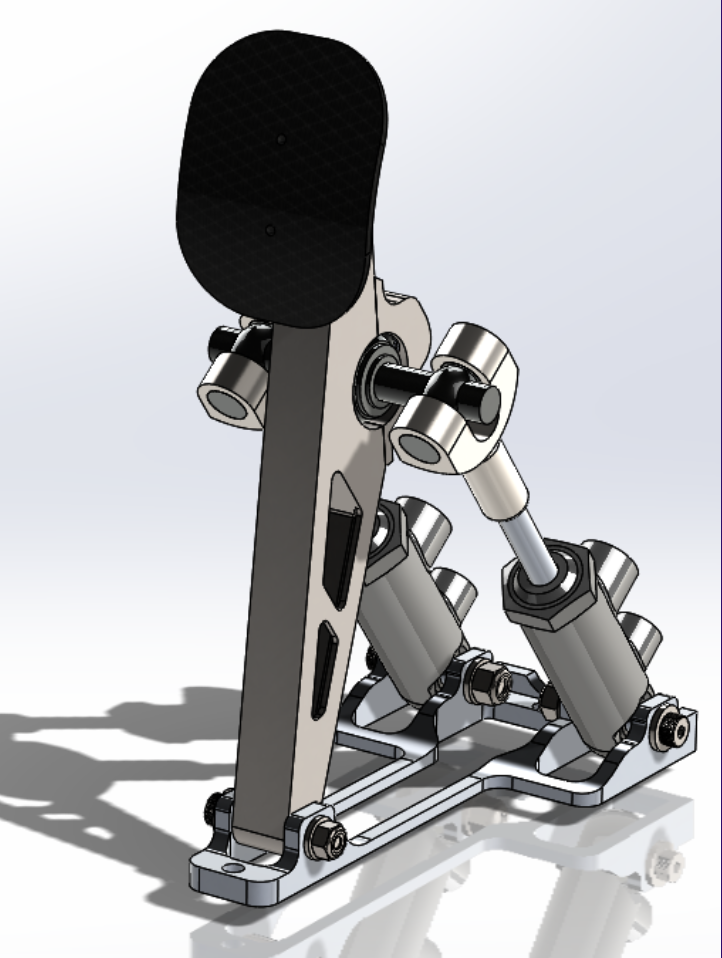

Model it.

Model of titanium brake pedal assembly.

-

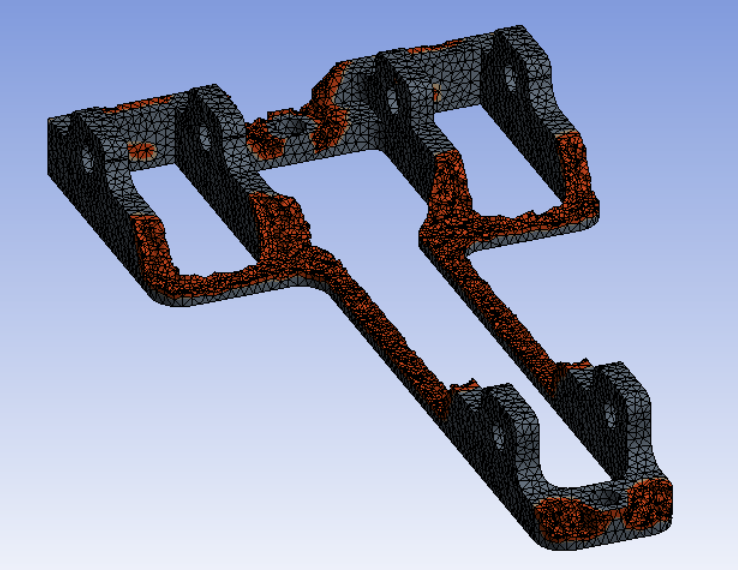

Test it.

Static structural simulation for brake pedal, 7075 aluminum, under maximum loading.

Key considerations for the simulation include inspecting for areas of heightened stress, strain, and deformation.

-

Iterate.

Result of a topology simulation on the base of the braking system.

The simulations were cyclically fed from static structural, topology optimization , and buckling analysis tools to achieve the final product.

Results

(In grams)

Brake Arm

Brake Base

Throttle Arm

Throttle Base

TOTAL (g)

T30

149.87

230.36

74.94

46.60

501.77

T31

138.15

184.37

69.45

30.38

442.35

Final Assembly

-

Lighter mechanical system.

Customizable FEA optimization program with Ansys.

Allows for streamlined workflow.

-

Optimize fastener size for weight saving purposes.

Using pins and clips instead of bolts*.

-

Further investigation into FEA boundary conditions to save on computing time.